Panels with A-grade and B-grade veneer faces are always sanded smooth in manufacture to fulfill the requirements of their intended end use – applications such as cabinets, shelving, furniture, built-ins, etc. Still other panels – APA Underlayment, APA Rated Sturd-I-Floor, APA C-D Plugged and APA C-C Plugged – require only touch-sanding for "sizing" to make the panel thickness more uniform. Sanded panels are fully sanded to a smooth surface while touch-sanded panels are sanded but perhaps not as uniformly as the sanded panels. It should be noted that when presented with moisture in the form of humidity, vapor or liquid, the grain of the wood is likely to raise and the surface become more uneven. Download Sanded Plywood, Form K435, for more information.

Sanded panels can be manufactured in a variety of ways – as plywood (cross-laminated wood veneer), as composites (veneer faces bonded to wood strand cores), or rarely as oriented strand board (OSB).

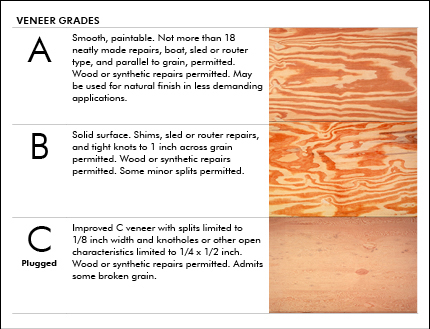

For full description of veneer grades, consult Panel Design Specification, Form D510

For full description of veneer grades, consult Panel Design Specification, Form D510

Bond Durability Classification

For many industrial-type applications, including product and system components, truck trailer liners, crates and pallet decks, Exposure 1 panels are suitable. For uses not permanently exposed to elevated moisture exposure, especially export packaging and refrigeration applications, Exterior panels are recommended for repeated wetting and redrying or long-term exposure to weather or other conditions of similar severity. For more information on the difference in bond durability classification, visit the Durability page.

Species of Wood

Plywood is manufactured from more than 70 species of wood. These species are divided on the basis of strength and stiffness into five groups under Voluntary Product Standard PS 1, Structural Plywood, Form L870. Strongest species are in Group 1; the least strong in Group 5 (see Table 1 in PS 1). The group number that appears in the trademark on some APA trademarked panels – primarily sanded grades – is based on the species used for face and back veneers. Where face and back veneers are not from the same species group, the higher group number is used, except for sanded panels 3/8-inch thick or less and decorative panels of any thickness. These are identified by face species because they are chosen primarily for appearance and used in applications where structural strength is not critical. Sanded panels greater than 3/8-inch thick are identified by face species if C- or D-grade backs are at least 1/8-inch thick and are no more than one species group number higher than the face veneer group number. Some species are used widely in panel manufacture; others rarely. Check local availability if a particular species is desired.

Span Ratings

The Span Ratings in the trademarks on APA Rated Sturd-I-Floor appear as a single number. When plywood, APA Rated Sturd-I-Floor panels have a puncture-resistant face. The Span Ratings of 16, 20, 24, 32 and 48 inches are assigned to APA Rated Sturd-I-Floor. The larger the Span Rating number, the stronger the panel regardless of thickness. Sanded panels other than fully sanded Rated Sturd-I-Floor panels do not have Span Ratings.

Panel Orientation

The strength axis, or original long panel dimension (unless the strength axis is otherwise identified), should typically run across the supporting members for greatest strength.