Boat & Ship Manufacturing

Wood has been used in boat manufacturing for centuries. But the one drawback to this classic boat building material is that wood, when subjected to long-term high moisture conditions, may be susceptible to rot. Today’s pressure-preservative-treated wood addresses that concern and makes wood the best material for boat manufacture. It’s strong, impact resistant, and, because it’s treated, it can withstand the demands of permanent exposure to marine environments. Consider it a life preserver for your boat.

Where is Wood Used?

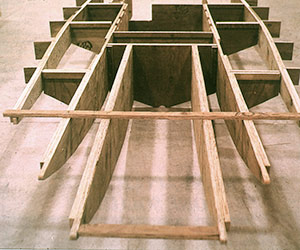

Many modern boat builders use wood products and fiberglass to make “hybrid” boats. Together, the system works to take advantage of the stiffness and strength of both the fiberglass and the plywood. Wood is typically used for the boat’s hidden structural components to maximize the boat’s performance and durability. These components include:

Many modern boat builders use wood products and fiberglass to make “hybrid” boats. Together, the system works to take advantage of the stiffness and strength of both the fiberglass and the plywood. Wood is typically used for the boat’s hidden structural components to maximize the boat’s performance and durability. These components include:

- Stringers – Provides superior strength and impact resistance for a smooth ride in rough seas.

- Floors – Provides a solid floor that is unmatched for fastener-holding ability. This means no loose seats and a solid platform for other floor-mounted equipment.

- Transom – The transom is critical to a boat’s structural integrity. Wood delivers the required strength needed to transfer all of the engine’s horsepower through the boat’s hull.

- Interior – Treated wood is able to withstand periodic exposure to seawater without decaying or deteriorating. It’s an ideal material for use in boat cabinetry, walls, seating, and other interior fixtures.

Treated Woods

Treated wood is impregnated with preservatives by a pressure process. The resulting deep penetration of preservative provides protection against decay and insect attack. Because the pressure treating process locks the preservatives into the cell structure of the wood, the preservatives don’t leach out. The wood that is used in boat manufacture is treated with the same pressure-preservative process that’s applied to lumber used in common applications such as decks, park benches, and playground equipment. Treated wood is also used for posts and poles that are buried in the ground and subjected to continual exposure to moist soil. Pressure-preservative-treated wood lasts. Whether the wood in a boat is encased in other protective products such as fiberglass or is exposed directly to seawater, treated wood does not rot. In fact, most suppliers of pressure-preservative-treated plywood to the marine industry include a limited lifetime warranty against rot or delamination.

Treated wood is impregnated with preservatives by a pressure process. The resulting deep penetration of preservative provides protection against decay and insect attack. Because the pressure treating process locks the preservatives into the cell structure of the wood, the preservatives don’t leach out. The wood that is used in boat manufacture is treated with the same pressure-preservative process that’s applied to lumber used in common applications such as decks, park benches, and playground equipment. Treated wood is also used for posts and poles that are buried in the ground and subjected to continual exposure to moist soil. Pressure-preservative-treated wood lasts. Whether the wood in a boat is encased in other protective products such as fiberglass or is exposed directly to seawater, treated wood does not rot. In fact, most suppliers of pressure-preservative-treated plywood to the marine industry include a limited lifetime warranty against rot or delamination.

Marine Grade Plywood

For boat-building applications, a special grade of plywood, APA Marine Exterior, is available. Marine grade plywood is a premium panel using the same moisture-resistant glues as regular Exterior plywood, but manufactured with only Douglas-fir or Western Larch veneers, and with additional restrictions on veneer grade, core gaps, patches and other characteristics.

The grade of all plies of veneer is B or better. B-grade veneer may have knots but no knotholes. A-grade veneer has no knots or knotholes. Both A and B grade may contain wood or synthetic patches. Panels are sanded on both faces or Medium Density Overlay (MDO) or High Density Overlay (HDO). The maximum core-gap size permitted is 1/8 inch. Its exposure durability rating is Exterior and the glue used is a moisture-resistant structural adhesive. It is considered a "premium" panel grade for use in situations where these characteristics are required. It is available in 4x8-foot sheets of 1/4, 3/8, 1/2, 5/8 and 3/4-inch thickness. Sheets up to 5x12-feet are also available. Available grades are A-A, A-B, B-B (face-back), MDO and HDO.

Marine grade should be used where bending strength is important, such as boat hulls. Basic Exterior-type plywood may be used for most other applications in boat construction. Plywood panels rated as Exterior but not Marine, such as A-B, A-A or C-C Exterior, may contain any other permissible species and contain C-grade veneer. Unless specially improved, C-grade veneer is permitted to contain knots and knotholes up to approximately 1-1/2 inches across, and the inner plies may have core gaps up to 1-inch wide.

Marine grade should be used where bending strength is important, such as boat hulls. Basic Exterior-type plywood may be used for most other applications in boat construction. Plywood panels rated as Exterior but not Marine, such as A-B, A-A or C-C Exterior, may contain any other permissible species and contain C-grade veneer. Unless specially improved, C-grade veneer is permitted to contain knots and knotholes up to approximately 1-1/2 inches across, and the inner plies may have core gaps up to 1-inch wide.

Publications

Data File: Preservative-Treated Plywood

This data file includes specifications, uses and advantages, acceptances, technical data, and finishing recommendations and identification for preservative-treated plywood.